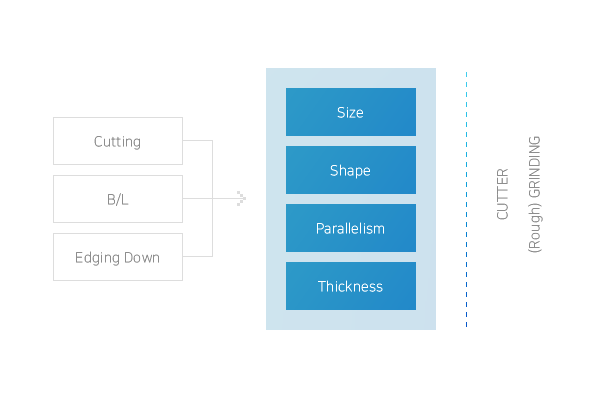

FABRICATIONS

-

Opticlines is a leading manufacturer of visible and IR optical components.

Manufacturing processes include : spherical generating,

flat plane generating, edge process ...

The techniques used for these operations range

from high-speed production to fine hand finishing by master opticians.

The equipment capability to provide custom,

some-dimensional shapes of fabricated optical components

for integration into custom frames. -

-

Materials

- Glass : BK-7, Fused Silica

- Sapphire

- IR Materials : Ge, Si, ZnSe, ZnS

-

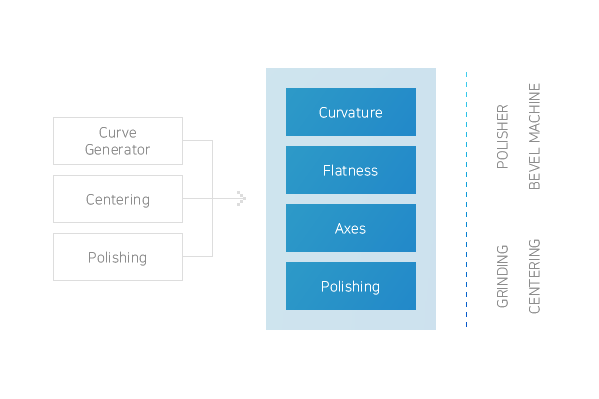

OPTICAL POLISHING

-

Opticlines utilizes various polishing equipment

for a precision generating and a polishing of various optics,

including on a variety of spindle polishers,

double-sided polishers, and various sized planetary polishers.

In addition, opticlines has an extensive capability

for hand finishing of unique crystals. -

-

Applications

- S/D : 10/5 ~ 60/40

- Flatness : λ/10, λ/8, λ/4, λ/2

- window, prism, lens, sapphire

-

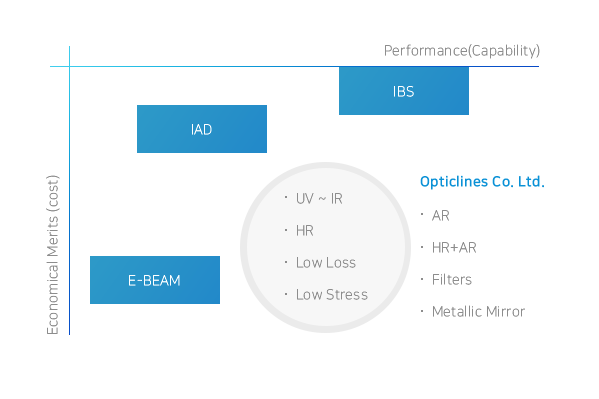

COATINGS

-

Opticlines is a recognized leader in the application of visible

and infrared thin film coatings for a wide variety of substrate materials.

Opticlines' coatings have been proven to withstand a variety of hostile

environmental conditions such as severe abrasion,

including the windshield wiper test, salt-water submersion, rain erosion,

missile exhaust, humidity, and salt fog. -

-

Material

- Dielectric such as HfO2,

- SiO2, Ta2O5, ZrO2...

- Metallic elements such as

Ge, Ag, Cu, Al, Cr, Au...

Required Layers

- AR : several ~ dozens

- HR : several tens layers

- IBS : > several tens

-

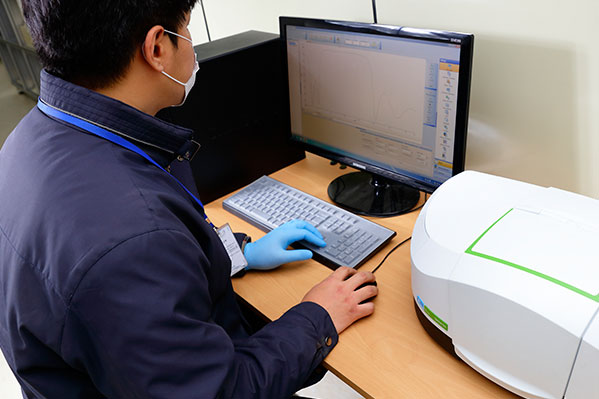

Quality & TEST

-

Provide quality through planning, control, improvement

and shared experience.

Focus on rigorous, unrelenting discipline throughout the entire

engineering process and emphasize total customer satisfaction.

Develop common initiatives and drive for continuous improvement.

Optimize supplier and product quality through early development

participation and eliminate defects through process control,

product robustness, operator involvement. -

-

-

Intensity Spectrometer

Point Resolution

Thin Film

Spectrometer

Jig -Continuum

@SCAN

(UV ~ IR) -

Interferometrics

Mirror Position, Original Aperture,

Laser Power, Light Damping -